Publicación:

12. Sep 2025

Última actualización:

27. Oct 2025

News & Blog

From VDI 2019 to DIN ISO 813-2

Liability lives up to what the standard promises

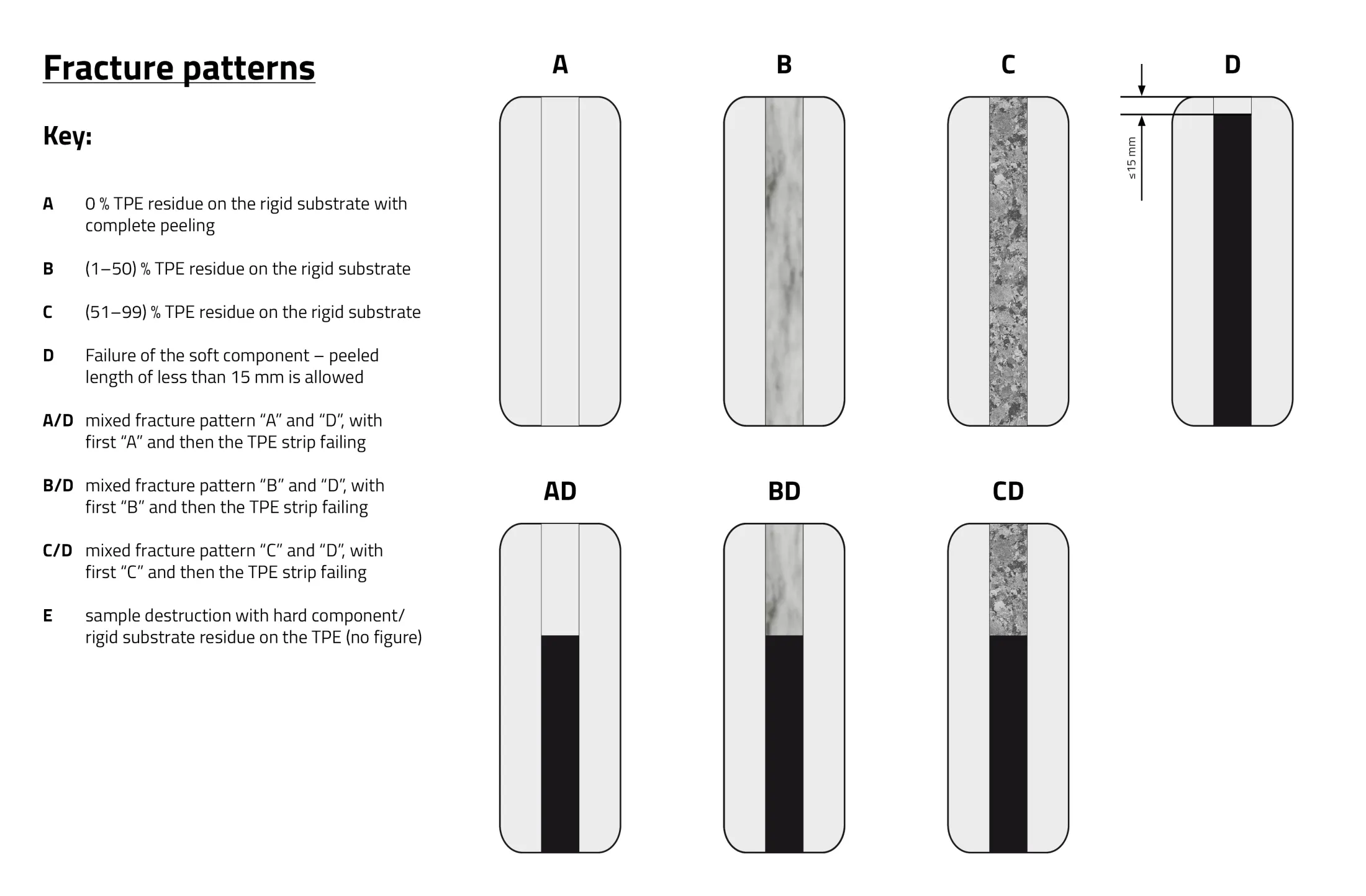

Josef Neuer, Head of Product Management, and Dieter Pauler, Head of Testing Laboratory at KRAIBURG TPE, provide information about the new DIN ISO 813-2 standard, which replaces VDI 2019 at national and international level. We are delighted that our colleague Dieter Pauler played a key role in the development of this standard. Read more here about the test procedure for the adhesive strength of thermoplastic elastomers to various hard components.

Gain insights from the Experts

Webinar

Thermoplastic Elastomers: The Basics

This 30-minute introductory session aims at TPE beginners as well as advanced users, and will focus on different TPE classes, (dis-)advantages of TPS materials, attributes of TPS as well as its composition.