New EPDM Adhesion TPE-Compounds

These compounds set a new standard in material technology, offering adhesion, durability and processability.

KRAIBURG TPE Introduces New EPDM Adhesion Compounds for Automotive Industry

KRAIBURG TPE unveils its latest innovation: Thermoplastic Elastomers (TPE) with EPDM adhesion for automotive sealing systems and exteriors. These compounds set a new standard in material technology, offering adhesion, durability and processability. Available globally with comprehensive technical support on parts and processing, KRAIBURG TPE reaffirms its commitment to excellence in automotive solutions. This is to empower manufacturers to excel in their products with supply security and constant quality.

Waldkraiburg, Germany, 2 May 2024 – KRAIBURG TPE is launching new EPDM adhesion compounds designed for the automotive sealing and exterior sector, addressing global requirements and needs with particular focus on the markets in Europe, North, South and Central America. These compounds epitomize a remarkable leap in material technology, delivering adhesion, durability, and processability essential for demanding applications. Specifically formulated for automotive exterior parts with UV resistance, they find application in glass run channels and sealing profiles featuring molded corner joints and end caps. In close cooperation with one of the most important Tier 1 in automotive sealing businesses worldwide there have successful tests of the compounds in comprehensive trials since 2023. This release emphasizes the importance of the automotive sealing segment for KRAIBURG TPE and the company’s commitment to deliver high-quality solutions for OEMs and Tiers.

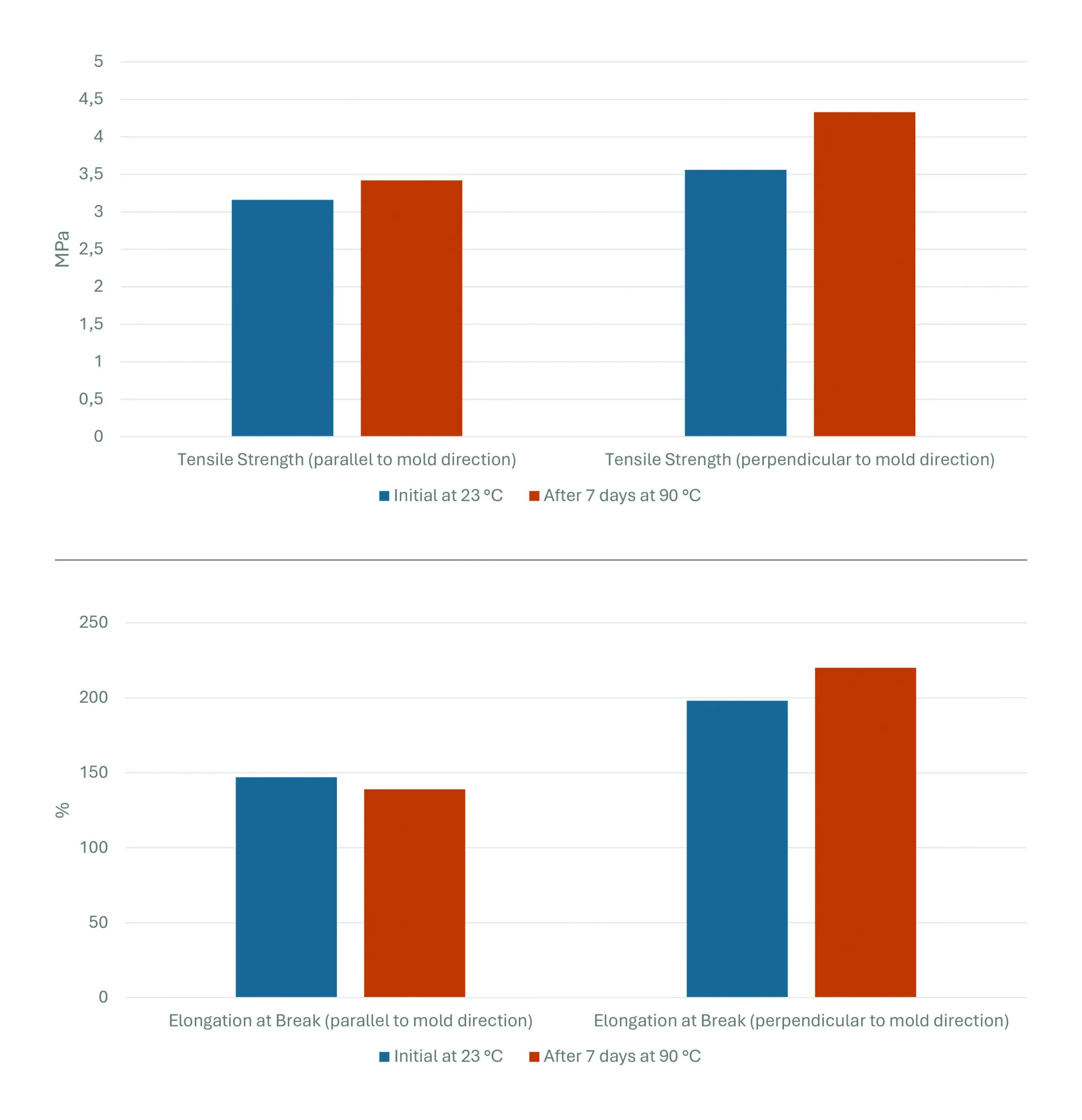

KRAIBURG TPE’s latest market introduction features constant EPDM adhesion quality proven at 23°C and 90°C heat aging, with dry surface appearance. The optimized flow properties provide a broad processing window and increased design flexibility in part and tool design while maintaining high performance standards. Additionally, the compounds offer weathering resistance, color stability, low surface friction behavior and wear and tear resistance. The homogeneous surface quality enhances aesthetics and functionality, meeting the stringent requirements of automotive applications. Compared to full EPDM sealing solutions, TPE-EPDM hybrid technology meets market trends by supporting the transition to TPE for sealing systems due to process efficiency. A lower product carbon footprint as well as weight reduction support efforts towards sustainability.

Table: Adhesion of TC7RQP-BLCK (67 Shore A) to EPDM acc. WDK guideline 2701 “EPDM-TPE-Hybrid Components” (© KRAIBURG TPE)

Global Support and Supply

The new compounds address the needs of original equipment manufacturers (OEM), Tier 1 and Tier 2 in the automotive sealing and exterior industry as well as tool makers. Products are available worldwide, ensuring accessibility and support for manufacturers across the globe. The KRAIBURG TPE service package offers unparalleled support, including assistance with the TPE approval processes at global OEMs, technical guidance, and global supply security with constant quality.

With the introduction of the enhanced EPDM adhesion compounds, KRAIBURG TPE continues to lead the industry in providing innovative solutions for automotive sealing and exterior applications. The company’s commitment to quality, performance, and customer support remains unwavering to empower manufacturers to achieve excellence in their products.

To highlight the significance of this technology, KRAIBURG TPE also holds various patents for this new series in Europe and North America.

KRAIBURG TPE Quick Facts

- Founded in 2001 as an independent business unit of the KRAIBURG Group

- HQ & Production Site: Waldkraiburg / Germany

- Regional HQ & Production site: Kuala Lumpur / Malaysia, Atlanta / USA

- Products: Thermoplastic Elastomer Compounds

- Brands: THERMOLAST®, COPEC®, HIPEX®, and For Tec E®

- Markets: EMEA, APAC, Americas

- Employees: 660