Resumen de los hechos más importantes

- Los elastómeros termoplásticos de poliamida (TPA) son copolímeros en bloque basados en poliamidas y compuestos de éter o poliamidas y compuestos de éster.

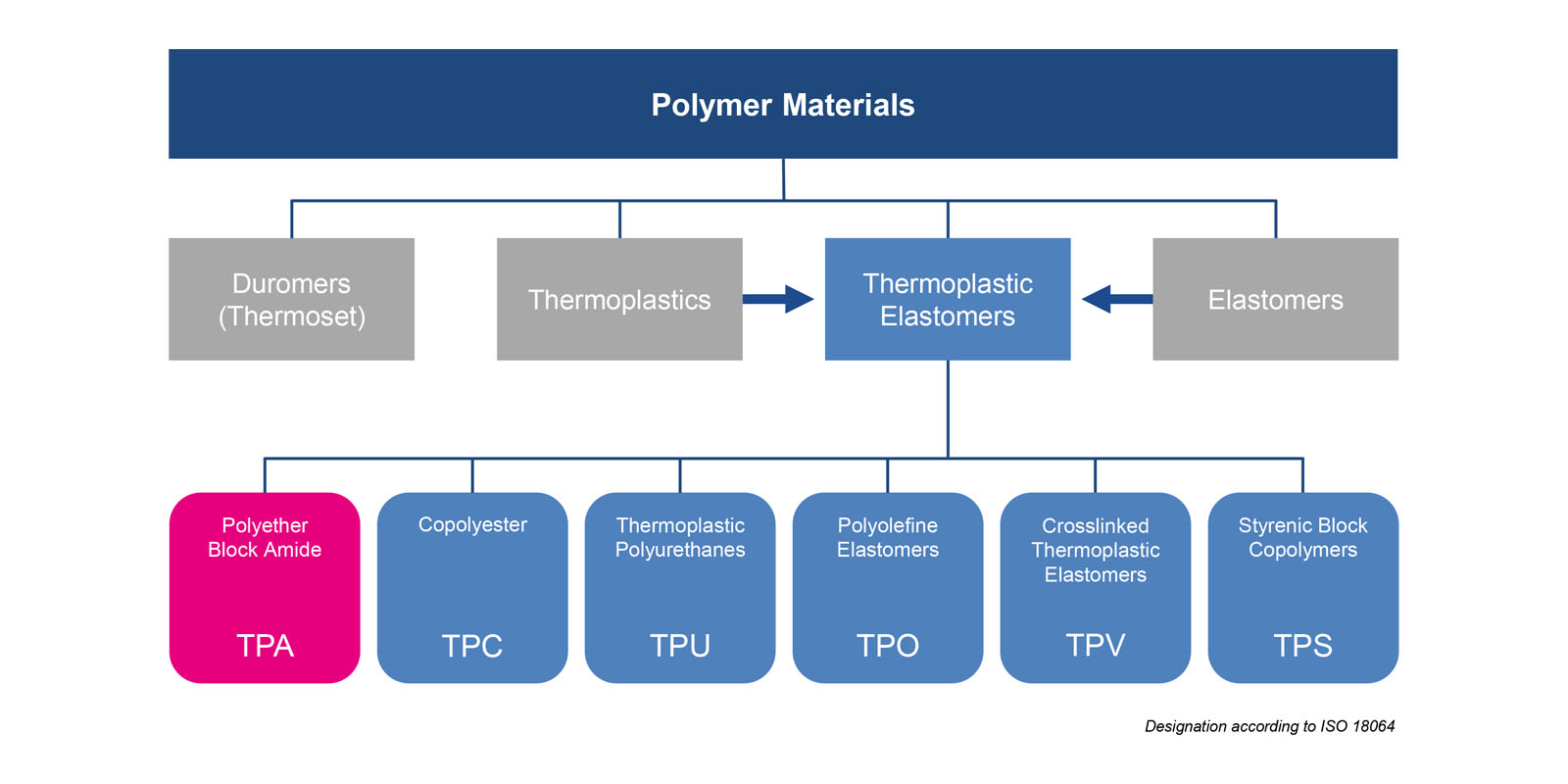

- Los TPA forman un subgrupo de los elastómeros termoplásticos.

- Los TPA se basan en poliamidas, que presentan una buena resistencia y robustez, así como una buena resistencia a temperaturas elevadas.

- Al igual que otros grupos de elastómeros termoplásticos, los TPA pueden procesarse mediante moldeo por inyección y extrusión.

¿Qué es el material TPA?

Los elastómeros termoplásticos de poliamida (TPA) son copolímeros en bloque basados en poliamidas y compuestos de éter o poliamidas y compuestos de éster. En la cadena polimérica, la poliamida (por ejemplo, PA6) representa la fase dura y los compuestos de éter o éster las fases blandas para las propiedades elásticas. Los TPA forman un subgrupo de los elastómeros termoplásticos.

¿Qué propiedades tiene un material TPA?

Los TPA se basan en poliamidas, que presentan una buena resistencia y robustez, así como una buena resistencia a temperaturas elevadas. Estas propiedades predestinan a los TPA para su uso en aplicaciones técnicas, como líneas de transporte de medios, o para artículos deportivos, como zapatillas deportivas y botas de esquí.

¿Cómo se procesan los TPA?

Al igual que otros grupos de elastómeros termoplásticos, los TPA pueden procesarse mediante moldeo por inyección y extrusión.

Encuentre la solución de TPE adecuada para su aplicación

Asegúrese de obtener los mejores resultados: se han desarrollado las soluciones de materiales adecuadas para cada una de sus aplicaciones específicas.

¿Fabrica KRAIBURG TPE TPA?

En los últimos años, KRAIBURG TPE se ha especializado principalmente en el desarrollo y la producción de productos TPS y TPV. Actualmente, KRAIBURG TPE no ofrece productos TPA.