最重要的事實簡述

- Thermoplastic polyolefins (TPO) are either a mixture of an olefinic thermoplastic and a non-crosslinked elastomer or an olefin copolymer.

- TPOs are characterized by good chemical resistance to acids, bases and ozone.

- TPO can be processed by injection molding and extrusion.

- KRAIBURG TPE offers special TPO-based compounds.

What is TPO?

Thermoplastic polyolefins (TPO) are either

- a mixture of an olefinic thermoplastic (e.g. PP) and a non-crosslinked elastomer (e.g. EPDM) or

- an olefin copolymer with a soft and a hard segment.

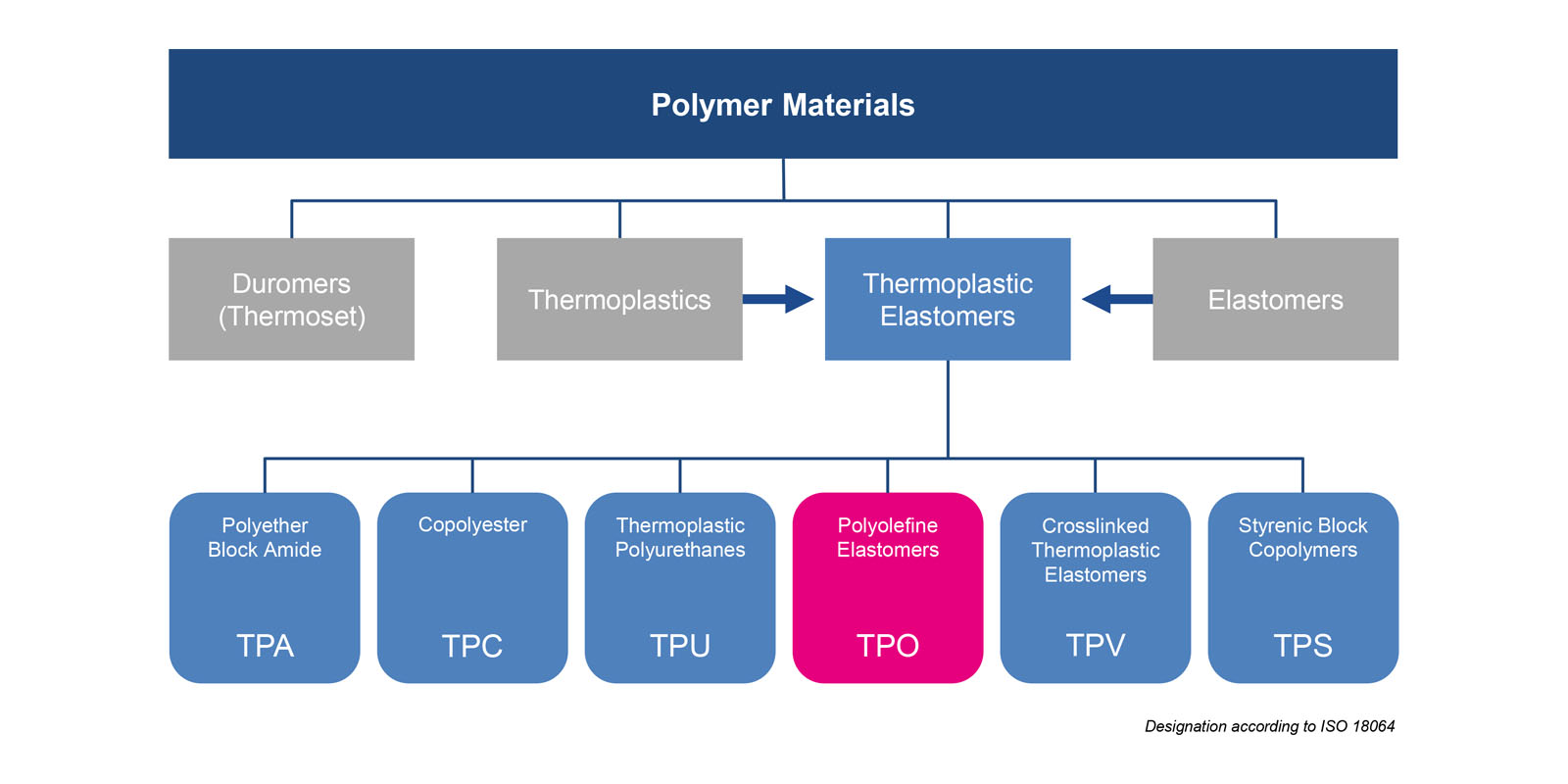

The materials form a subgroup of thermoplastic elastomers.

What are the properties of a TPO material?

TPOs settle in the medium and high Shore A range and are characterized by good chemical resistance to acids, bases and ozone, among other things.

How are TPO processed?

TPO, like other groups of thermoplastic elastomers, can be processed by injection molding and extrusion.

Find the right TPE solution for your application

Making sure you get the best results: the right materials solutions have been developed for each of your specific applications.

Does KRAIBURG TPE produce TPO?

In recent years, KRAIBURG TPE has specialized mainly in the development and production of TPS and TPV products. Nevertheless, KRAIBURG TPE offers special TPO-based compounds.