Processing Guides of TPE

Here you'll find valuable tips and answers to frequently asked questions about the processing of TPE (thermoplastic elastomers) through extrusion, injection molding, and co-extrusion. Leverage our expertise to achieve optimal results and effectively tackle any challenges you may encounter in your projects.

The Co-extrusion Process

Unlocking Innovation: The Power of the Co-extrusion Process

During co-extrusion, various plastics from different extruders or cylinders are joined together. The source materials are not mixed but bonded together in several layers by heating.

The Injection Molding Process

Discover how our injection molding delivers high-quality, custom plastic parts quickly and accurately.

Discover how advanced injection molding techniques enable high-quality, customized plastic parts with speed and accuracy.

The Extrusion Process

How are TPE processed during extrusion processes?

During extrusion, the source material is filled as granules into the screws. The high temperatures within the heated cylinder make the material melt. The nozzle brings the molten material into the desired profile shape. After cooling and solidifying, it can be cut to the desired lengths.

Discover suitable webinars

Contact our Team of Experts

Selected for you: similar articles

TPE Basics: In-process recycling

KRAIBURG TPE is introducing the most frequently requested industry terms in a series of blog posts. First up is "in-process recycling." This is an attribute that most TPE solutions from the competence leader have always had.

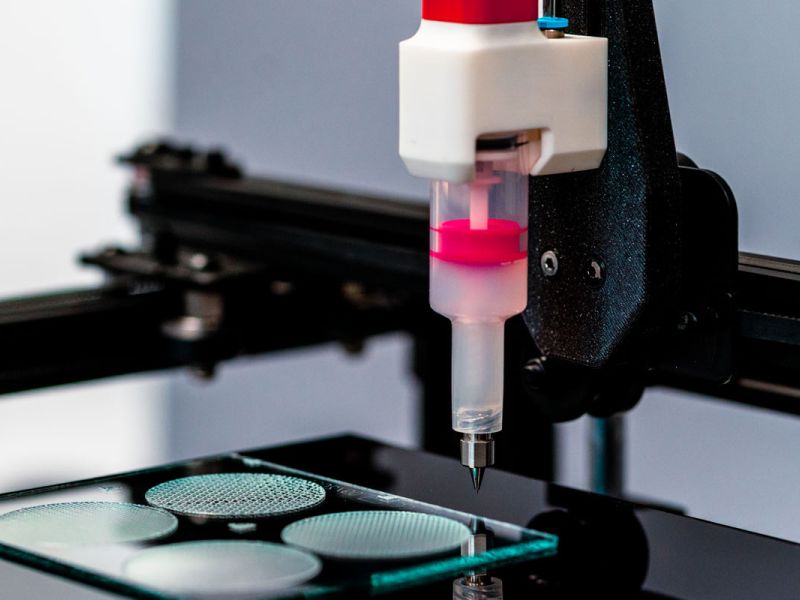

Bioprinting solution from ViscoTec relies on THERMOLAST® M

The manufacturer's goal is to apply biomaterials more precisely with the help of the Puredyne cap b5. The small stopper bears a great deal of responsibility in this regard, as its filigree design and material properties mean that even the difficult requirements for tightness in this particular field of application can be met optimally.